Reviving an Ancient Lost Fabric

A muslin weaver threads the ancient motif through the warp and weft threads on the loom while making a unique 'new muslin' jamdani sari. Image: Tapash Pal/Drik/Bengal Muslin.

Words by Holly Bodeker-Smith

Dhaka muslin was known as the world’s finest fabric for centuries. Yet by the 18th century, British colonisation had obliterated the artisanal craft behind this delicate material. This team took it upon themselves to bring this ancient, lost practice back to life in Bangladesh.

For centuries, Dhaka muslin was the world’s most revered fabric. Many in the upper echelons sought it out – including the ancient Greeks, the Romans, Marie Antoinette and Jane Austen. Dhaka muslin was so fine that it was called ‘woven air’, and so transparent that those who wore it looked naked – even when wearing several layers of it. “It’s so light you don’t feel that you’re wearing anything,” says Saiful Islam, leader of Bengal Muslin, the initiative reviving the lost fabric.

Dhaka muslin was long loved by those in the West. Yet the craft came from Bengal, now Bangladesh. Bengali artisans pioneered the 16-step process behind this fabric, which had some of the highest thread counts in history. At its peak, Dhaka muslin contained up to 1,200 fibres per square inch of fabric. Nothing below 250 was considered to be muslin. “The thread count of the clothes we wear today is probably between 40-60,” says Islam for comparison.

The detail that went into making Dhaka muslin was unparalleled. People picked the phuti karpas cotton plant, which only grew on the banks of the Meghna River. Artisans then cleaned the fine cotton balls using the jawbone of the boal (catfish), which had three rows of tiny teeth. High humidity was needed to stretch these short fibres into yarn, so young women would spin it on boats in the early mornings or late afternoons to avoid sunlight and soak up the humidity. It’s also said that tailors took opium before repairing Dhaka muslin for laser-sharp focus. “It was a six metre long cloth, and out of 2,500 threads they would be able to pick out one thread and put in a replacement thread. [They would examine] probably 120,000 threads as they went through the entire cloth,” says Islam.

Unable to find this level of quality elsewhere, traders came from around the world to buy ultra-fine Dhaka muslin. “A wave of colonial rulers have used Dhaka muslin and sold it around the world,” says Islam. “The Arabs came and started to trade in it, then the Portuguese, the Dutch, the French and [finally] the English.”

Yet it was the British who brought Dhaka muslin to the wider public, ultimately triggering its demise. In 1757, the British Raj had usurped the powers of the Mughal Dynasty through a one sided treaty. At the Imperial Exhibition in London a century later, the British displayed Dhaka muslin to great fanfare. “It was another example of colonisation,” says Islam. “Getting kudos by saying: these are the crafts in the empire. As if [the British] had a role in the development of the craft. Their only role was in the distribution and the exploitation of that craft.”

Soon enough, the British East India Company started plundering Dhaka muslin for its own power and profit. They turned the artisans into employees, which prevented them from selling to the highest bidder and sent many into debt. They also taxed anyone who owned a loom. “Every time you wove and gave the British something, the money you got went straight back as loom tax. The British were almost getting it for free.”

Zille from Germany is slowly putting the final touches in place on her art installation which was in the lobby of the Bangladesh National Museum during the Muslin Festival. Image: Habibul Haq/Drik/Bengal Muslin.

The 1770 Bengal famine all but decimated what remained of the craft. “The British were conquering China, so they kept grain for the troops in China. More than a third of [Bengal’s] population died. Weavers left their looms to grow food,” says Islam. The East India Company also documented the 16-step process and tried to replicate it back home using cheap Scottish labour, which increased competition for the Bengali weavers. By the 1780s, thousands of women were making replica Dhaka muslin in Lancashire, England. “They put spices inside the cloth, so that when the English public opened the cloth they’d think it was from India. They called it imperial muslin.” Historians claim that the British cut off weavers’ thumbs to suppress their craft, though direct evidence is hard to find. The craft died and by the 1860s, phuti karpas cotton was no longer cultivated. “It was a classic case where the craft met capitalism. In the end, the craft lost,” says Islam.

Islam first learned about Dhaka muslin in 2013. He was living in the UK and working with Drik – a Bangladeshi organisation that runs events focused on South Asia and the impact of colonisation. Drik asked Islam to take a Dhaka muslin exhibition to Bangladesh.

But, there were a few problems with that. First, Islam couldn’t find any Dhaka muslin remaining in Bangladesh (much of it was in British museums). Second, he couldn’t find any stories that weren’t told through a Western lens. “It seemed strange to me that we were taking an exhibition to the country where it was born [without any real examples].”

Islam attributed part of this to Bangladesh having multiple separations (with Partition in 1947 and the Liberation War in 1971) as well as being an oral society. “Often we pass on the skills to the next generation without writing them down,” he says.

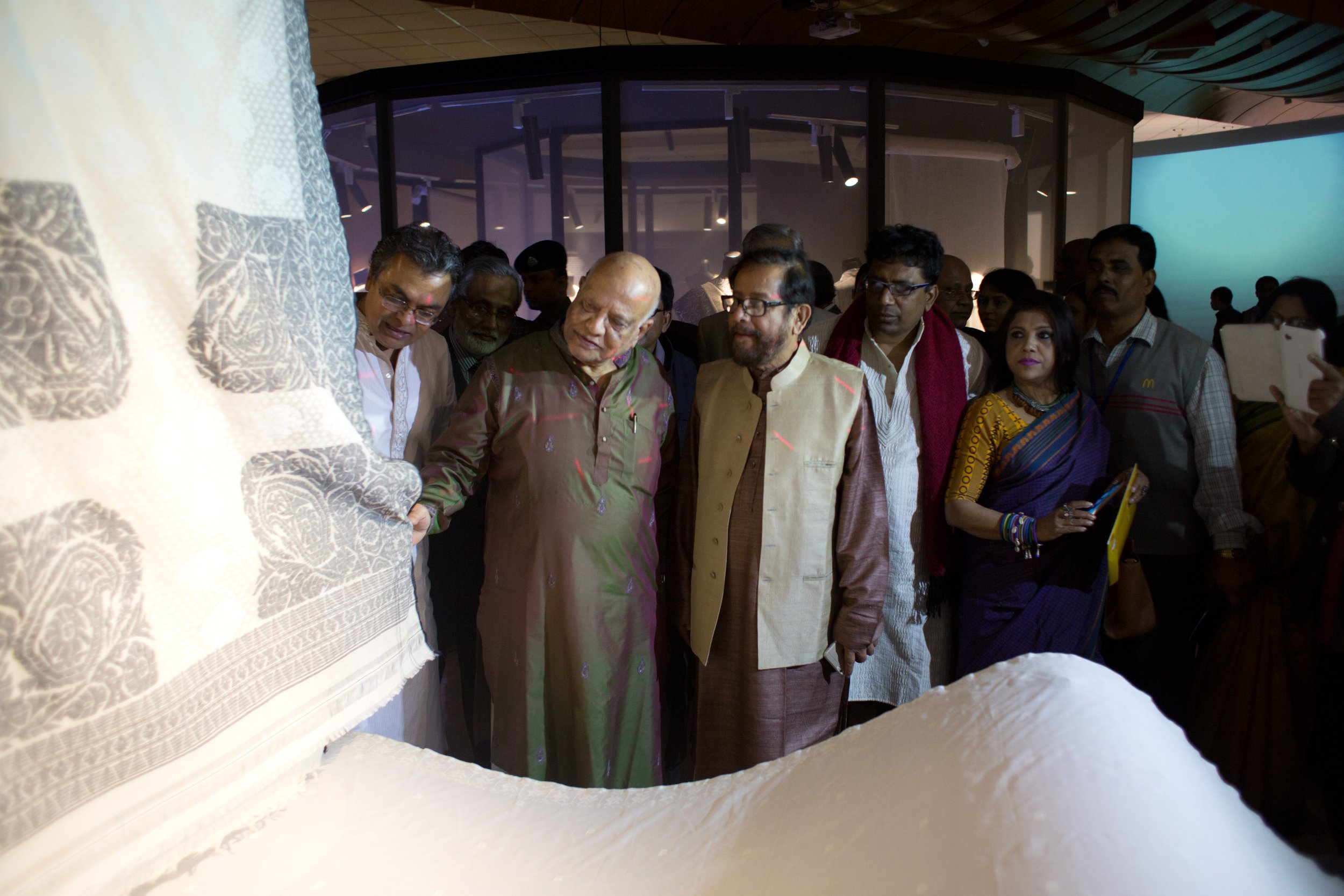

Finance Minister, M A Muhith and Cultural Affairs Minister, Asaduzzaman Khan inspecting the new muslin sari at the Muslin Festival. Image: Habibul Haq/Drik/Bengal Muslin.

So what did Islam and his team do? They learned as much about the craft as they could, and documented every step of the journey. Drik curated the exhibitions, while Islam wrote a book (Muslin. Our Story) and made a film (Legend of the Loom) about the story of Dhaka muslin.

Eventually, Islam realised it wasn’t enough to retell the story. He needed to bring Dhaka cotton back to life. Islam and his team sequenced the DNA of the phuti karpas, found a descendent plant and planted its seeds along the banks of the Meghna. They then created a hybrid thread of phuti karpas and Indian cotton, and found a weaver, Al Amin, who helped revive Dhaka muslin. Today, Islam and his team have created dozens of Dhaka muslin saris that have been exhibited and sold around the world.

Islam says that reviving Dhaka muslin felt like discovering a buried truth about Bangladesh. “I have the feeling that [this] was not about muslin alone. Maybe it was about us in Bangladesh having the confidence to say that nothing needs to be lost – whether it’s a species, language or music. Often these are lost unconsciously. It’s often the act of men – where there is benign neglect on our part.”

Historians claim that the British cut off weavers’ thumbs to suppress their craft, though direct evidence is hard to find.

“I have not found a single person who's held it and said ‘No, we don't want it’.”

The Bengal Muslin project shows that people can revive long-buried, artisanal crafts and rewrite the narratives of colonisation. There’s certainly demand for it. Their modern, Dhaka muslin saris have sold for thousands of pounds in high-end auction houses. “I have not found a single person who's held it and said ‘No, we don't want it’,” says Islam. “You hold it and you say: ‘Why can’t we have more of it?’”